Leave Your Message

Grease making is a vital process in various industries. Understanding the essential components is key to quality production. "Grease Making Raw Materials" play a critical role in the final product’s properties and performance.

Different types of raw materials are used, each providing unique characteristics. These include base oils, thickening agents, and additives. The right combination can improve the grease's stability and lubrication efficiency. However, determining the best materials can be challenging. Each choice carries implications for performance and cost.

It is important to reflect on the environmental impact too. Some raw materials may not be sustainable or eco-friendly. Balancing quality and environmental responsibility is crucial. In this overview, we will explore the top ten essential raw materials and their significance in grease production. Each entry highlights what you need to know for informed decision-making.

Essential oils play a vital role in grease production. They provide unique properties that enhance the quality of grease. These oils can improve lubrication, reduce friction, and increase stability. Their presence can also affect the scent of the final product. This is often overlooked but can influence customer preferences.

Several essential oils can be incorporated into grease formulations. For instance, lavender oil is known for its calming effect. It may not have a direct impact on performance, yet it adds a pleasant aroma. Some oils have anti-oxidative properties, helping to extend shelf life. Choosing the right essential oils is crucial, but it requires careful consideration.

The use of essential oils is not without challenges. Not all oils blend well with base materials. Sometimes, they can destabilize the grease. Testing is necessary to find the right balance. It is essential to focus on quality over quantity. Finding effective combinations can be complex yet rewarding. Each variation might bring something new to the table, pushing innovation further in grease production.

| Raw Material | Function | Source | Key Benefits |

|---|---|---|---|

| Lithium Soap | Thickener | Lithium salts | High temperature resistance |

| Calcium Soap | Thickener | Calcium salts | Water resistance |

| Sodium Soap | Thickener | Sodium salts | Cost-effective |

| Polymeric Thickener | Thickener | Synthetic polymers | Improved stability |

| Mineral Oil | Base oil | Petroleum | Good lubrication properties |

| Vegetable Oil | Base oil | Plants | Biodegradable |

| Additives | Performance enhancer | Various chemical compounds | Improved performance |

| Anti-oxidants | Stability | Phenolic compounds | Extended shelf life |

| EP Additives | Load carrying capacity | Various chemicals | Enhanced wear protection |

| Extenders | Modify consistency | Various natural and synthetic materials | Cost reduction |

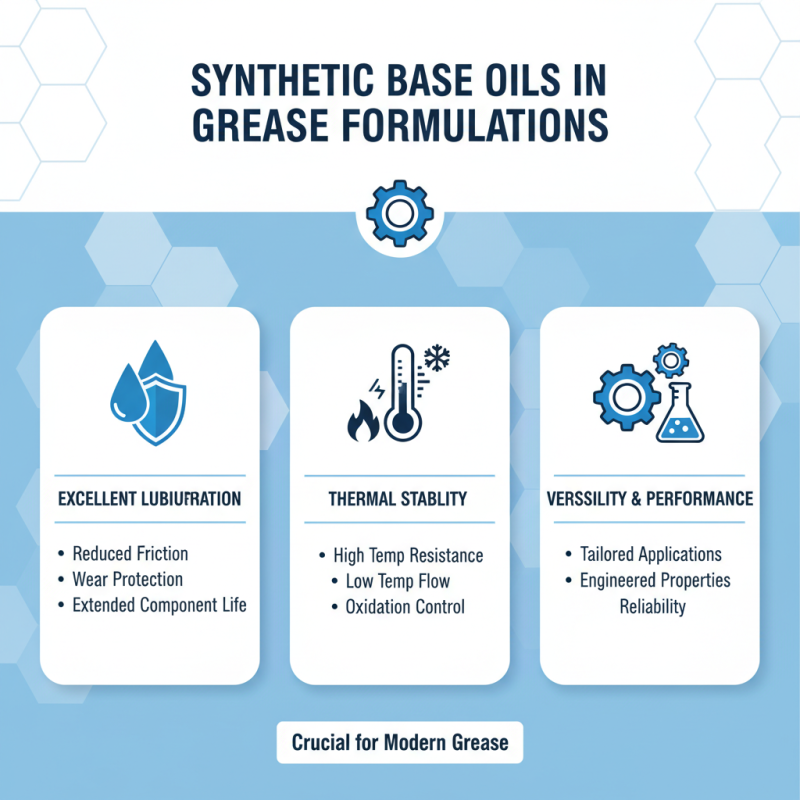

Synthetic base oils play a crucial role in modern grease formulations. They provide excellent lubrication properties and thermal stability. These oils are engineered to meet specific performance requirements. Their versatility allows them to be tailored for various applications, making them invaluable.

Crafting the right synthetic base oil is not always straightforward. Manufacturers face challenges in balancing cost and performance. The selection of the appropriate base oil can significantly impact the final product. It requires careful consideration of the desired characteristics, such as pour point and viscosity index.

Moreover, sustainability concerns arise with synthetic base oils. As the industry shifts towards more eco-friendly options, the sourcing of raw materials becomes vital. Exploration of bio-based alternatives is ongoing but might not always yield desired results. The journey toward optimal formulations blends innovation with challenges, prompting constant refinement and adaptation.

Thickeners play a vital role in grease production. These components ensure consistency and stability, affecting the overall quality of the grease. Without proper thickeners, grease can become too fluid or separated. The choice of a thickener influences performance in various applications.

Common thickeners include lithium soap and calcium soap. They help achieve the right viscosity. The balance of thickener impacts not just texture, but also the grease’s ability to withstand heat and shear. The wrong choice can lead to discordant results. It’s essential to test different combinations to find what works best.

**Tip:** Start with small batches when testing new thickeners. This allows for better control over your formulation.

Another critical factor is the quantity of thickener used. Too much can lead to brittleness, while too little can cause leaks. Each formulation requires careful measurements to ensure the intended characteristics. Experimenting can lead to unexpected results. Be prepared for imperfections in your first attempts.

**Tip:** Document your improvements during the testing phase. This can help in analyzing what works and what doesn’t.

In the world of grease formulation, additives play a crucial role. They enhance performance and offer protection. Using the right additives can significantly improve the characteristics of grease. For instance, anti-wear additives can increase the lifespan of machinery by reducing friction. According to industry reports, incorporating these additives can boost operational efficiency by 30%.

Tips: Always test additives in small batches. This helps to identify the best combination for your specific application. Experimentation may lead to unexpected results. Not every additive will perform as expected. Monitor the results closely and be ready to adjust.

Thickeners are another vital category of additives. They help maintain consistency in grease. Different thickeners can affect drop points and flow characteristics. Some thickeners can handle extreme temperatures, enhancing stability. Yet, not all thickeners are compatible with every base oil. Understanding this relationship is key to optimal performance.

Tips: Consider the environmental conditions where the grease will be used. Ensure that the chosen thickeners offer the necessary protection against extreme conditions. Sometimes, common choices may not suit specific applications, leading to potential failures.

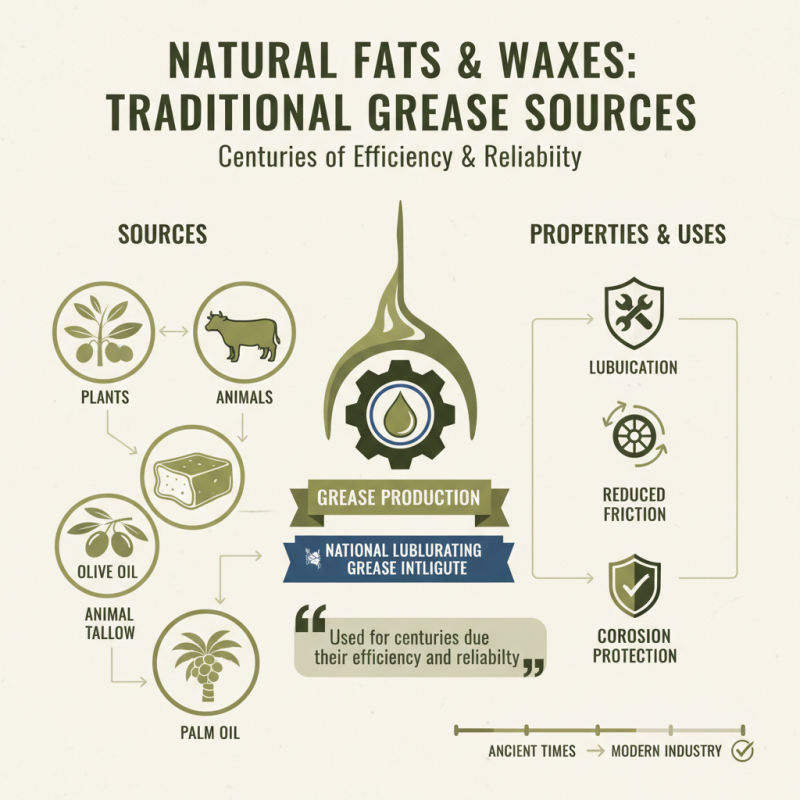

Natural fats and waxes serve as traditional sources for grease production. They are derived from various plants and animals, offering unique properties. According to the National Lubricating Grease Institute, these materials have been used for centuries due to their efficiency and reliability. Common natural fats include olive oil, animal tallow, and palm oil, which have made their mark in the industry.

Tip: When selecting fats, consider the melting point and oxidative stability. These factors significantly affect the grease's performance. High-quality fats provide better lubrication and reduce wear, while lower quality may lead to issues over time.

Be aware, however, that sourcing these materials can be challenging. Environmental impact and sustainable practices are essential considerations. Ethical sourcing ensures that production meets industry standards. It is crucial to reflect on how these choices impact the environment and the communities involved in production.

Tip: Always research suppliers thoroughly. Understanding their practices can help ensure you are choosing sustainable options. The grease industry is evolving, making awareness of these factors more important than ever. Consider the long-term implications of your material choices.