Leave Your Message

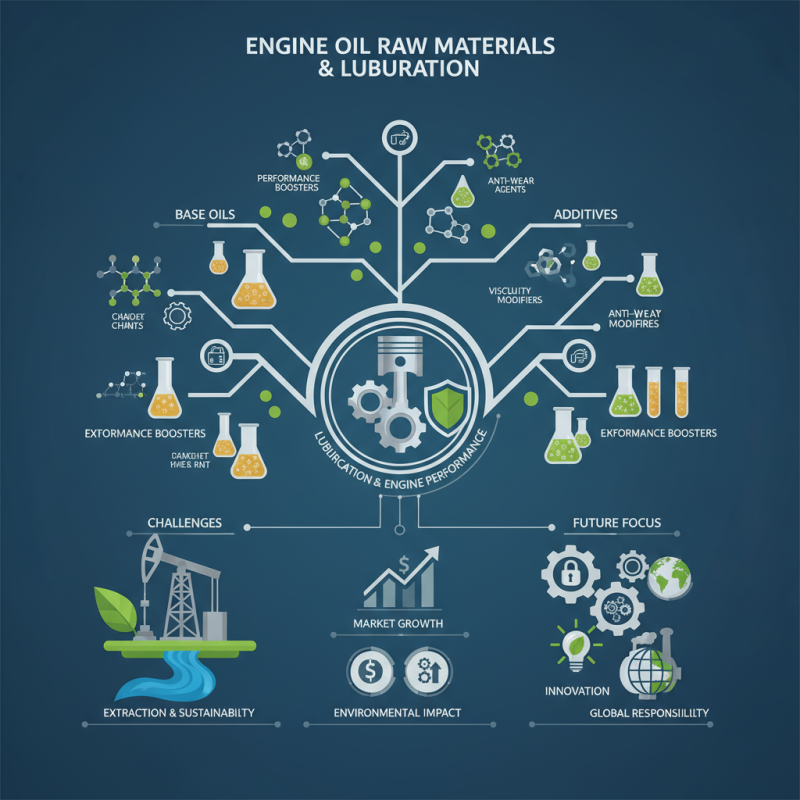

Engine Oil Raw Materials play a crucial role in the lubrication industry. Lubricants reduce friction, enhance performance, and prolong engine life. According to a recent report by the American Petroleum Institute, the global lubricants market is expected to reach $100 billion by 2025. This growth highlights the significance of quality raw materials in producing effective engine oils.

Dr. Elaine Peterson, a renowned expert in lubricant formulation, emphasizes, “The right raw materials make a significant difference in engine performance and longevity.” Without high-quality base oils and additives, engine oils cannot perform optimally. However, sourcing these materials can be challenging. Environmental concerns about extraction and production processes can often complicate the supply chain.

Understanding Engine Oil Raw Materials is essential for manufacturers. It impacts not only product performance but also environmental sustainability. The industry must continuously seek innovative solutions. These challenges necessitate careful consideration of material selection. Balancing cost, performance, and environmental impact remains a pressing issue.

Engine oil raw materials are essential for creating effective lubricants. These materials include base oils and additives. Base oils can be derived from mineral, synthetic, or bio-based sources. Each type has unique characteristics. Mineral oils are the most commonly used, derived from refining crude oil. They are often more affordable but may have variability in quality.

Additives play a critical role as well. These substances enhance the performance of base oils. They help reduce friction, prevent oxidation, and improve temperature stability. Common additives include detergents, anti-wear agents, and viscosity modifiers. The choice of additive can significantly impact oil performance.

Understanding these raw materials is vital. It informs decisions regarding engine maintenance. However, not all engines require the same formulation. This discrepancy can lead to misuse if not addressed. Many professionals stress the importance of selecting the right type of oil for specific engines.

This chart illustrates the different types of raw materials used in engine oil and their significance in lubrication. Each material plays a crucial role in enhancing the performance and protection of engine components.

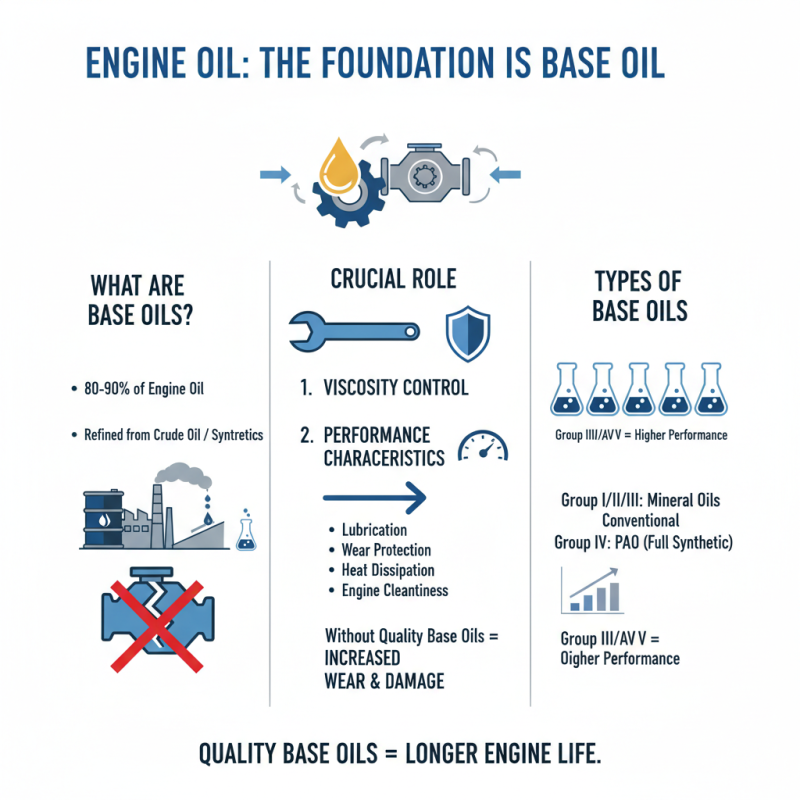

Base oils play a crucial role in the formulation of engine oils. They are the primary components that determine the oil's viscosity and performance characteristics. Without quality base oils, engine oils may fail to provide adequate lubrication. This could lead to increased wear and damage.

Different types of base oils exist, each with unique properties. Mineral oils are derived from crude oil, while synthetic oils are chemically engineered for specific performance features. Understanding these differences is important. For example, synthetic oils often perform better in extreme temperatures. Yet, they can be more expensive.

The balance between cost and performance requires careful thought. Some users may opt for cheaper oils, but this can affect engine longevity. Inadequate lubrication can lead to issues that are costly to repair. Making informed choices about base oils can enhance engine efficiency and protect against premature wear. Each decision carries potential consequences, and it’s essential to reflect on the long-term impact.

Engine oil is crucial for the smooth operation of an engine. Its effectiveness comes not just from the base oil, but also from various additives. These additives enhance the oil's performance in several ways. They improve lubricity, prevent corrosion, and reduce friction. This is vital for maintaining engine longevity.

There are several types of additives. Detergents are included to keep engine components clean. Without them, sludge can build up and hinder performance. Dispersants help manage soot and contaminants, ensuring they remain suspended. Antioxidants are key as they inhibit oil breakdown. This is essential for maintaining the oil's protective properties over time.

**Tips:** Regular oil changes keep additives fresh. Over time, they break down and lose efficiency. Pay attention to your engine's performance; sluggishness may indicate oil failure. Always use oils that meet specific requirements for your engine type. Remember, not all oils are created equal, and using the wrong type can lead to issues.

The quality of engine oil heavily relies on its raw materials.

These materials include base oils and additives. Base oils account for

70-90% of engine oil. High-quality base oils lead to better lubrication

and protection against wear. According to a recent industry report, engine oils with superior base stocks can improve

engine efficiency by up to 5%.

Additives play a crucial role in enhancing performance. They combat oxidation and reduce foam. However, not all

additives deliver the same benefits. Some cheaper formulations can lead to sludge formation. Poor-quality raw materials may seem cost-effective initially, but they can significantly

shorten oil lifespan. Studies indicate that low-grade oils fail to maintain viscosity within the first

1,500 miles. This premature breakdown can damage

engine components over time.

The importance of selecting the right raw materials

cannot be overstated. It influences engine longevity and performance. Consumers often overlook this aspect, focusing

more on price than quality. Over time, using inferior products may result in costly repairs. It’s essential to

reflect on these choices to ensure optimal engine health.

Sustainable sourcing of raw materials for engine oil is crucial. A report by the Global Sustainability Forum highlights that about 60% of the world's lubricants production comes from non-renewable sources. This statistic raises questions about long-term environmental impact. Relying on fossil fuels leads to resource depletion and pollution.

Innovative alternatives are emerging in the industry. Bio-based oils, derived from renewable sources, can reduce dependence on fossil fuels. According to a study by the Institute of Lubrication Engineers, these oils can diminish carbon emissions by up to 30%. However, challenges such as cost-effectiveness and performance consistency still exist. Companies need to prioritize research and development in this area.

The urgency for sustainable practices drives change. A survey found that 78% of consumers prefer eco-friendly products. This rising demand suggests a shift towards greener alternatives in engine oils. Yet, many manufacturers still hesitate to invest in sustainable materials. They often fear that the initial costs may outweigh the benefits. This hesitation provides an opportunity for improvement and innovation in sourcing strategies.