Leave Your Message

In the world of product formulations, choosing the right Primary Emulsifier is crucial. Industry expert Dr. Emily Richards emphasizes, “The right emulsifier can transform a product’s texture and stability.” This statement highlights the importance of selecting effective ingredients in formulation processes.

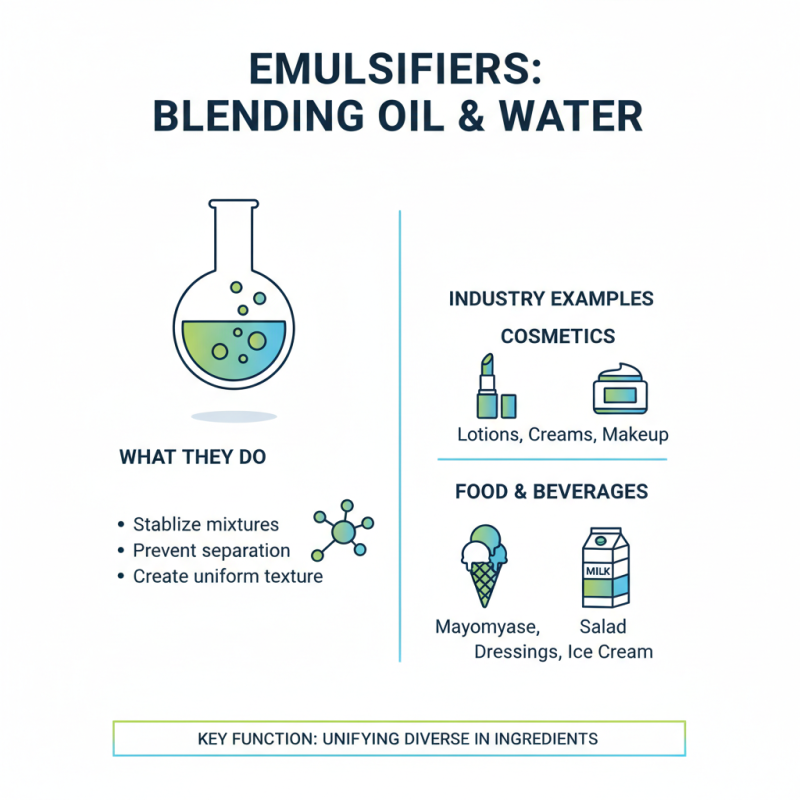

Primary Emulsifiers serve as the backbone of countless cosmetic and food products. They help blend oil and water, ensuring consistency and performance. However, finding the perfect emulsifier for a specific formulation can be challenging. Different emulsifiers have unique properties. The search for the ideal one requires careful consideration.

Formulators often face tough decisions. What works for one product may not suit another. Understanding the characteristics of various Primary Emulsifiers is essential. Some might be too heavy, while others could create unstable mixtures. This complexity requires ongoing research and experimentation. The quest for an effective Primary Emulsifier is never straightforward. Each formulation can present new challenges and opportunities for improvement.

When selecting primary emulsifiers, several key characteristics deserve attention. The right emulsifier should provide stability to the formulation. This means it can effectively blend oil and water phases. Consider the type of emulsifier: anionic, cationic, or nonionic. Each has its pros and cons. For instance, anionic emulsifiers work well in alkaline products, but may destabilize in acidic environments. Nonionic ones are often more versatile.

Another crucial factor is the emulsifier's HLB (Hydrophilic-Lipophilic Balance) value. This dictates the emulsifier's affinity for water or oil. A low HLB is suitable for water-in-oil emulsions, while a high HLB works for oil-in-water formulations. It’s also essential to evaluate the emulsifiers' sensory attributes. Texture, feel, and aesthetic quality can significantly influence user experience. Sometimes, emulsifiers can lead to a greasy residue, which is undesirable.

Finally, compatibility with other ingredients is vital. Some emulsifiers may react negatively with active compounds and cause separation. This potential issue should not be overlooked. Before finalizing a choice, conducting small-scale tests can reveal how they perform in real conditions. Emulsifiers can be tricky. What works in theory may not always translate seamlessly into practice. Always be open to revisiting initial selections based on testing outcomes.

Emulsifiers play a crucial role in product formulations across many industries. These substances help stabilize mixtures of oil and water. Many emulsifiers exist, each with unique properties. Some work better for cosmetics, while others are suited for food products.

Commonly used emulsifiers include natural options like beeswax and soy lecithin. These ingredients are popular due to their wide availability and safety. Synthetic emulsifiers, such as polyglycerol esters, also hold a significant place. They offer strong stability, although some raise concerns about skin irritation. Users must be careful when selecting emulsifiers for sensitive formulations.

While numerous emulsifiers are effective, they can also have limitations. Not all emulsifiers behave the same way under varying temperatures. For example, some may lose stability in high heat. It's essential to test formulations under realistic conditions. The choice of emulsifier impacts texture and shelf life directly. Careful consideration and experimentation are vital for achieving desired results. Some may require multiple tests before settling on the right option.

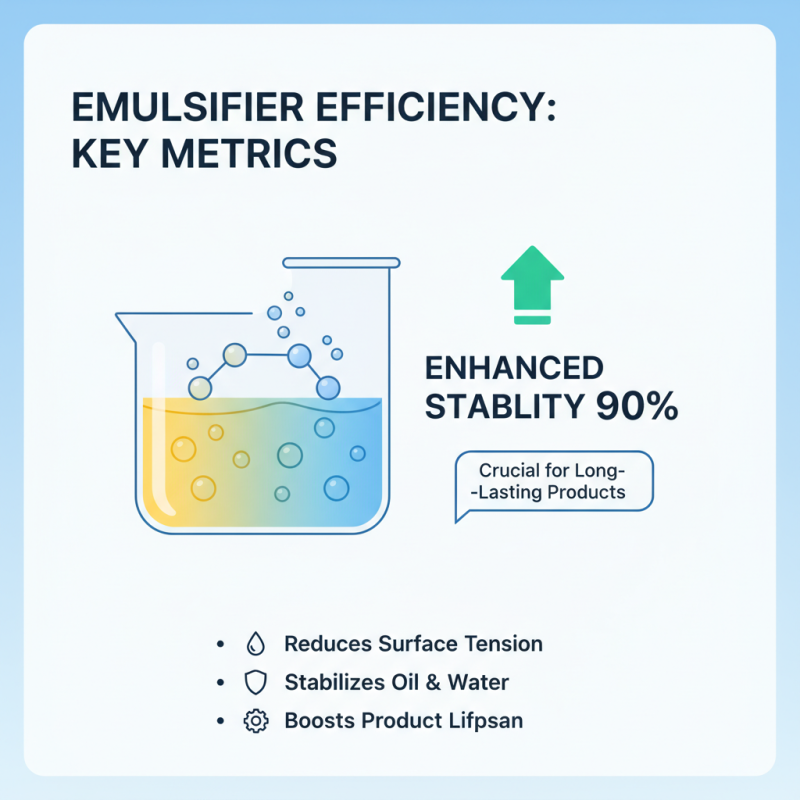

When evaluating emulsifier efficiency, performance metrics are crucial. Emulsifiers play a key role in stabilizing mixtures of oil and water. They reduce the surface tension between these immiscible liquids. A recent industry report highlighted that effective emulsifiers can enhance stability by up to 90%. This efficiency is essential for formulators aiming for long-lasting products.

Different emulsifiers exhibit varied performance under specific conditions. For instance, HLB (Hydrophilic-Lipophilic Balance) values can significantly influence the choice of emulsifiers. A higher HLB often indicates a better ability to stabilize oil-in-water emulsions. Data shows that formulations utilizing the right HLB can improve droplet size distribution and prevent separation. This ultimately leads to better texture and feel.

However, not all emulsifiers perform flawlessly. Some can reduce the overall stability of a formulation. Poor selection can lead to phase separation. A study found that nearly 30% of emulsions faced instability due to inadequate emulsifier choice. Continuous assessment of emulsifier performance is vital for achieving optimal product results. Careful testing and adjustments based on these metrics can make a significant difference.

When selecting primary emulsifiers for product formulations, regulatory standards play a crucial role. These guidelines ensure safety and efficacy in products. Emulsifiers must be evaluated for their compliance with local and international regulations. Each region may have different requirements that can affect ingredient selection. Understanding these regulations can streamline formulation processes.

The challenge often lies in balancing functionality and compliance. Some emulsifiers that perform well may not meet regulatory standards. For instance, an ingredient might enhance stability but be restricted in certain markets. Companies must remain aware of ingredient status and adjust formulations accordingly. Sometimes, the alternatives may not deliver the same results. This can create a frustrating cycle of trial and error.

Companies should also consider consumer trends. Natural and organic certifications are gaining importance. A natural emulsifier may comply with these standards, but functionality could vary. There is a constant need for reformulation and testing. Relying on a broad range of emulsifiers can be beneficial. This approach allows flexibility in meeting both regulatory standards and customer expectations. It is essential to stay informed and adaptable to succeed in the market.

The future of emulsifiers lies in innovation and sustainability. With growing consumer awareness, the demand for eco-friendly alternatives is rising. Many formulators are exploring plant-based options. These alternatives can often perform as well as traditional emulsifiers. However, the transition is not without challenges. Sourcing sustainable materials can be complicated. Not all natural emulsifiers provide the same stability or performance.

Emerging trends emphasize bio-based emulsifiers that are not only effective but also reduce environmental impact. Researchers are experimenting with new sources, like seaweeds and other botanicals. The push towards circular economy principles is influencing formulations. It's essential to rethink waste and byproducts in the emulsification process. Often, formulators overlook the long-term implications of their choices. Integrating sustainability into formulation strategies can be messy, with many variables to consider.

The industry is in a state of flux. Innovations in emulsifier technology must balance efficacy with eco-friendliness. Collaboration among scientists, formulators, and manufacturers is vital. This ensures that products not only meet consumer needs but also address environmental concerns. Yet, there’s a fine line between innovation and practicality. The path towards truly sustainable emulsifiers requires dedication and continuous learning.